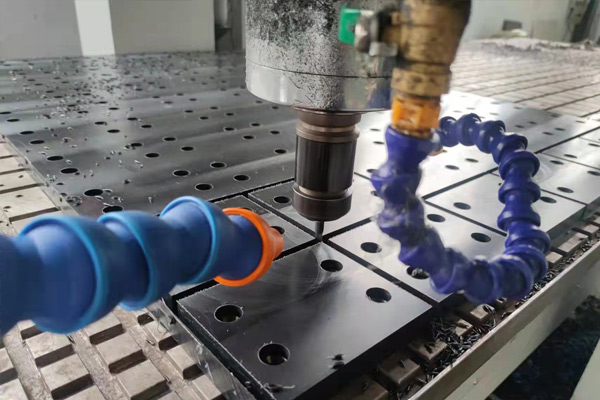

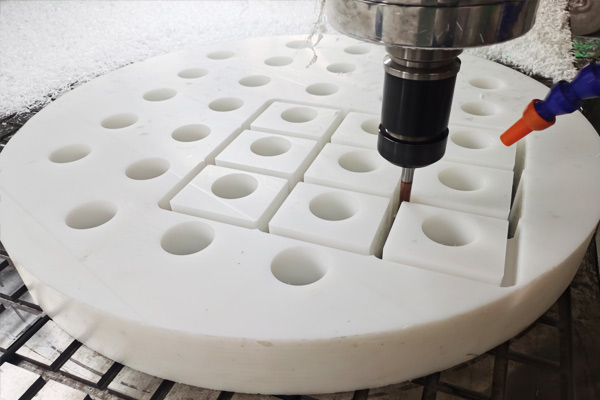

Processing Equipment

WHY CHOOSE US

Ningjin County Huarun Rubber & Plastic Co., Ltd.

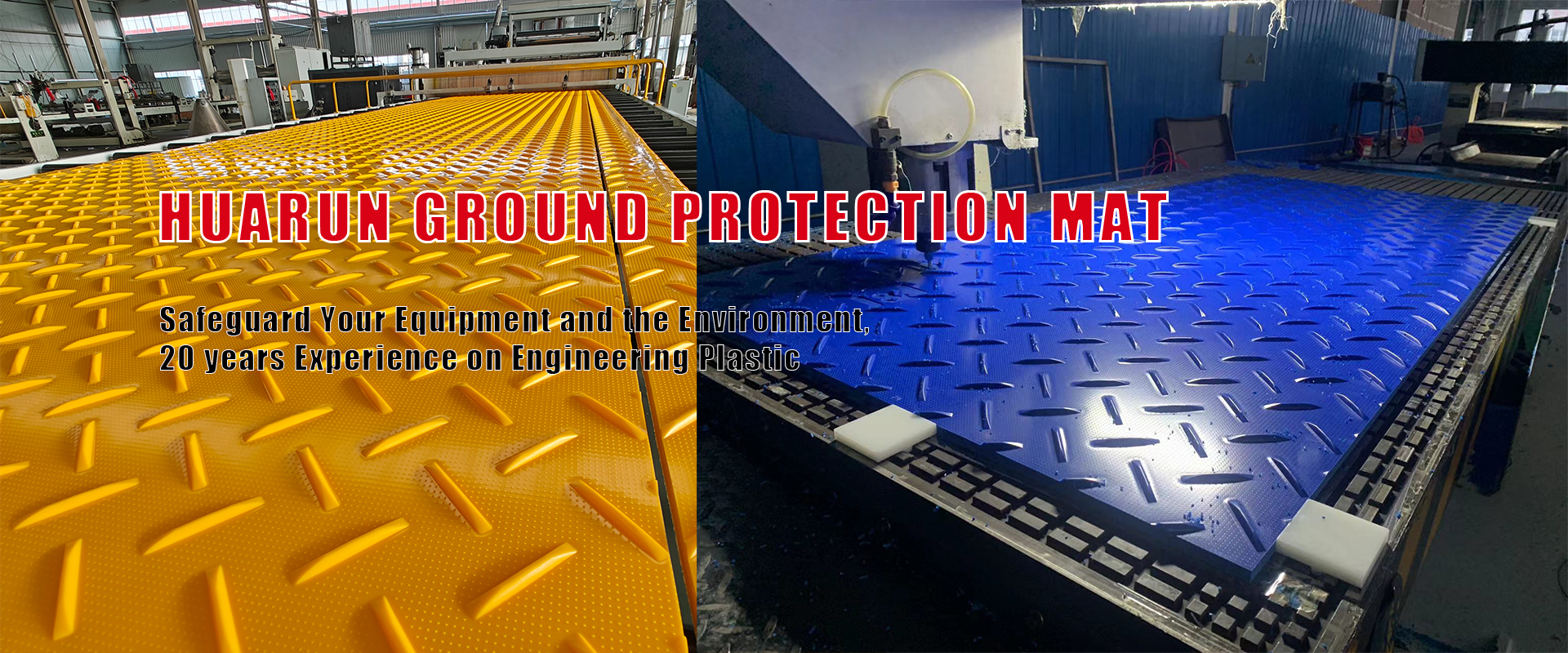

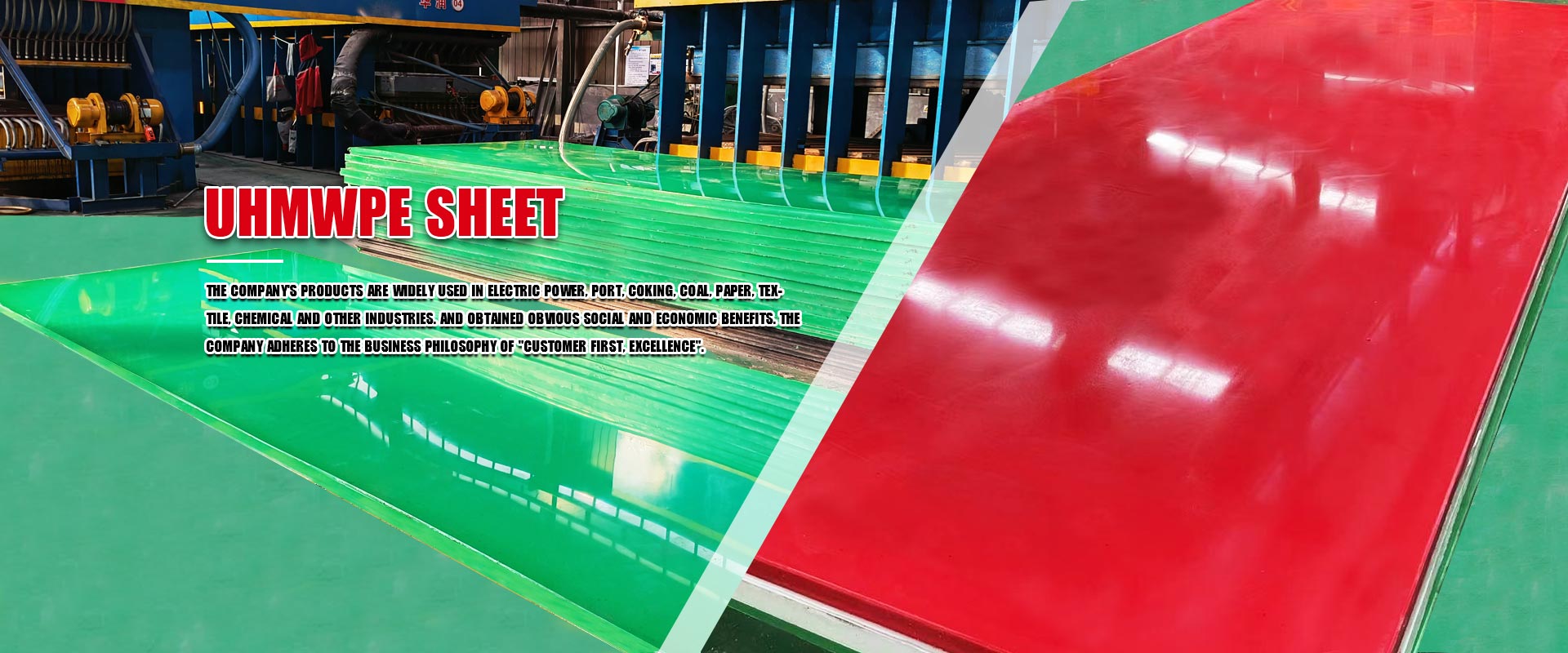

Ningjin County Huarun Rubber & Plastic Co., Ltd. is located in Xitang Industrial Park, Dacao Town. The company has a complete organizational structure and strong technical force, with processing and production equipment, high-quality design, production and construction teams. The company's products are widely used in electric power, port, coking, coal, paper, textile, chemical and other industries. And obtained obvious social and economic benefits. The company adheres to the business philosophy of "customer first, excellence". At present, we are working tirelessly with professionalism and striving to achieve the grand goal of enriching the country and strengthening the people through industry and building a harmonious socialist society!

APPLICATION INDUSTRY

Widely used in electric power, coal, chemical industry, coking, port, heavy industry machinery and other industries.

NEWS

Obtained obvious social benefits andEconomic benefits, favored by our customers.

The pe sheet becomes soft when heated, and can be bent according to requirements

Mark the part that needs to be bent with a pencil

Cut the pe sheet to be processed according to the size, pay attention to the accuracy of the size;

CONTACT US

Phone: 0086 13225346599

E-mail: alvin@sdhrxs.com

Address: Xitang Industrial Park, Dacao Town, Ningjin County, Dezhou City, Shandong Province

Website: www.njhrxs.cn

FEEDBACK

Copyright © 2024 Ningjin County Huarun Rubber & Plastic Co., Ltd.